Customer Service

Share your contact information – our engineers respond 24/7.

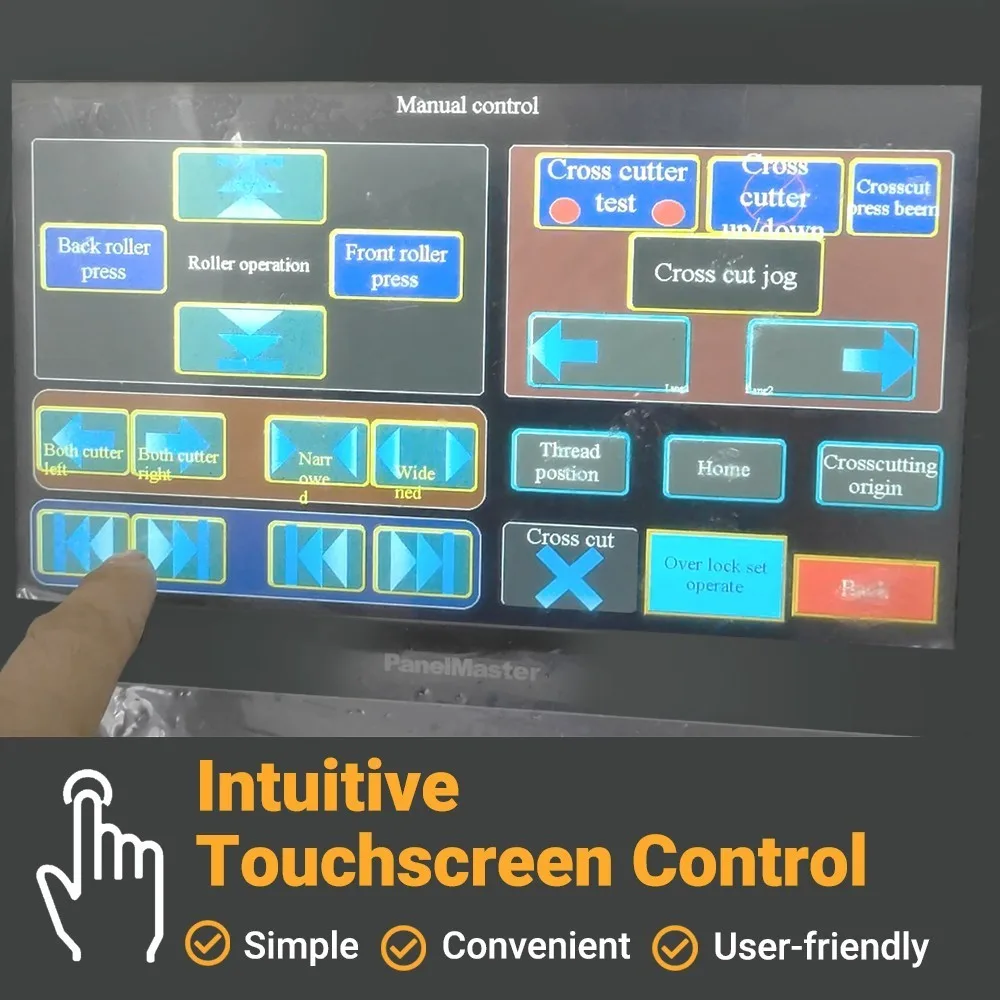

CJS Panel Hemming System integrates cutting and four-side overlock sewing into fully automated process. Features adjustable presser foot, digital controls, and compatibility with existing multineedle quilting machines. Delivers 2-4% material savings with consistent quality and fluffy tape edging.

Download PDF

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Dimension(L*W*H) | 3235*4065*2035mm | Sewing Width | 1000-2400mm |

Maximum Sewing Thickness | ≤80mm | Stitch Length | 3-12mm |

Power | 10KW | Gross Weigtht | 28000kg |

Voltage | 380/220V,3P,50/60Hz | Production Speed | 2-3pcs/min |

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Share your contact information – our engineers respond 24/7.

Panel Hemming Machine eliminates manual labor, cuts and hems simultaneously in one pass, provides perfect dimensional accuracy, and processes panels 5x faster than conventional manual flanging operations.

No. Panel Hemming Machine integrates cutting and hemming functions, eliminating the need for a separate panel cutting machine and saving equipment costs of $25,000-$40,000.

Yes. Panel Hemming Machine is designed to adapt to any existing multi-needle quilter, regardless of brand, model, or width. It integrates seamlessly into your current production line.

Panel Hemming Machine operates approximately 5 times faster than manual flanging operations, significantly increasing daily production capacity.

Standard purchase includes the complete machine, Omron control system, installation support, operator training, technical documentation, and warranty coverage.

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

FB Series Tape Edge Machines deliver high-speed sewing for all mattress types with exceptional flexibility and precise tape edge application. Built with ergonomic design combining operator comfort with maximum efficiency for reliable manufacturing productivity across any mattress style.

Download FB3 PDF

Download FB5 PDF

Download PDF

Download PDF

Discover how GENMAX can provide the perfect mattress machinery solutions for your business. Click below to send your inquiry and receive a customized proposal from our expert team. Let’s work together to achieve your success!

Share your contact information – our engineers respond 24/7.