Customer Service

Share your contact information – our engineers respond 24/7.

KB Series Heavy-Duty Flanging Machine sews ultra-thick mattress panels up to 90mm with HO HSING servo motor at 4,500 rpm. Features automatic presser foot lifting, encoder-controlled needle positioning, and vacuum removal system for mattress, upholstery, and home textile applications.

Download PDF

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

MODEL | KB1A | KB3K | KB4 | KB4A | KB6A |

|---|---|---|---|---|---|

Max Sewing Thickness | 60mm | 70mm | 70mm | 80mm | 90mm |

Type Of Sewing Head | Re-model of Domestic Head | KINFTEX | JUKI 6900---6916 | PEGASUS | JUKI 6900 |

Press Foot Lift | 12mm | 15mm | 15mm | 15mm | 35mm |

Number of Sewing Threads | 4thread | 4thread | 5thread | 4thread | 5thread |

Feeding Method | Pressfoot | Pressfoot | Belt | Pressfoot | Belt |

Motor Power | 600W | 550W | 550W | 550W | 750W |

Flanging Width | 25mm | 15/25/30/35mm | 25mm | 15/25/30mm | 25mm |

Air Pressure | 0.4-0.8Mpa | 0.4-0.8Mpa | 0.4-0.8Mpa | 0.4-0.8Mpa | 0.4-0.8Mpa |

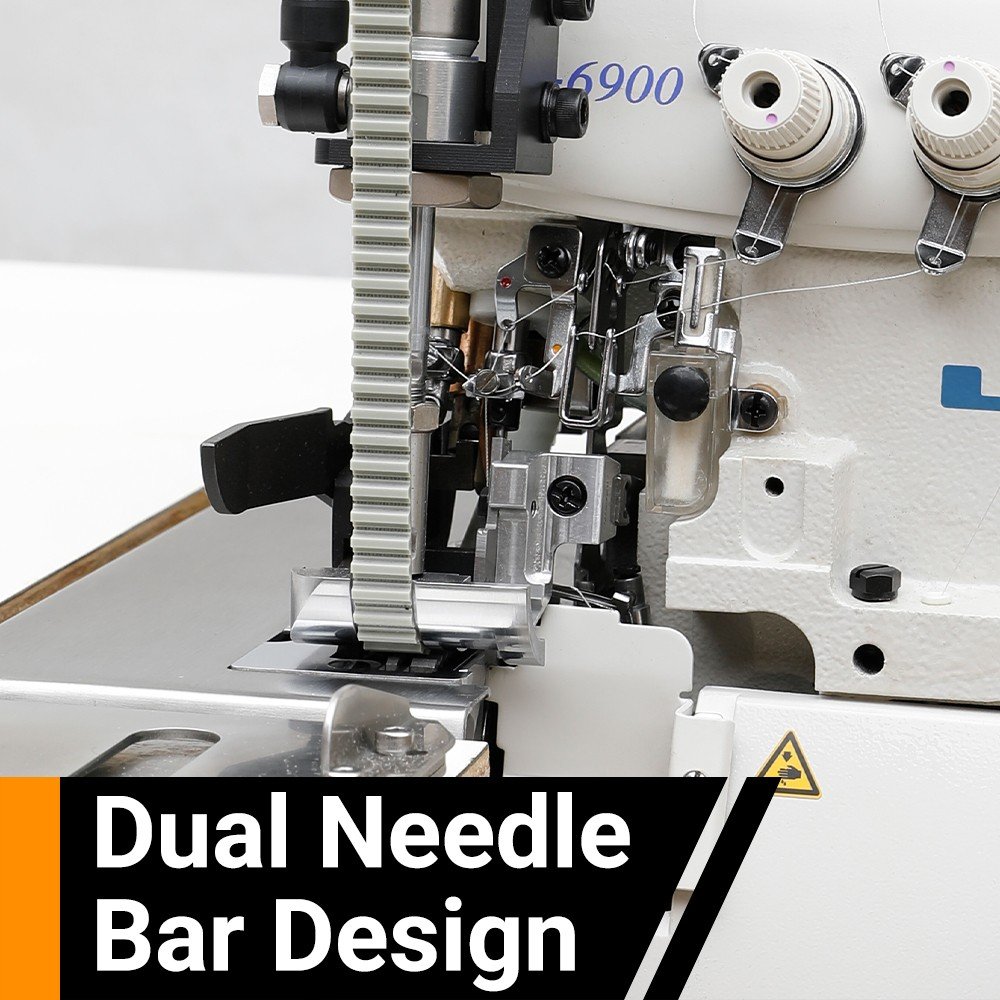

Needle Bar Type | Double Bar | Double Bar | Double Bar | Double Bar | Double Bar |

Max Sewing Speed | 3000RPM | 3000RPM | 3000RPM | 3000RPM | 4500RPM |

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

It’s a specialized sewing machine used in mattress production to stitch border material to the top and bottom panels, creating reinforced edges that can then be attached to the mattress sides.

Flanging strengthens the mattress structure, prevents fabric unraveling, improves appearance, and prepares panels for final assembly.

Sewing head (needle, bobbin, thread system)

Needle assembly (needle, presser foot, feed dogs)

Thread tension mechanism

Fabric feeding system (rollers, belts, guides)

Control panel (stitch length, speed, tension)

Frame & table (support and work surface)

Setup (load needle, bobbin, adjust tension)

Feed mattress panels through the machine

Stitch border material to edges

Inspect and adjust for quality

Stronger, more durable mattresses

Smooth, professional-looking edges

Faster production with automation

Lower labor costs and fewer errors

Flexibility for different fabrics and stitch types

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

FB Series Tape Edge Machines deliver high-speed sewing for all mattress types with exceptional flexibility and precise tape edge application. Built with ergonomic design combining operator comfort with maximum efficiency for reliable manufacturing productivity across any mattress style.

Download FB3 PDF

Download FB5 PDF

Download PDF

Download PDF

Discover how GENMAX can provide the perfect mattress machinery solutions for your business. Click below to send your inquiry and receive a customized proposal from our expert team. Let’s work together to achieve your success!

Share your contact information – our engineers respond 24/7.