Customer Service

Share your contact information – our engineers respond 24/7.

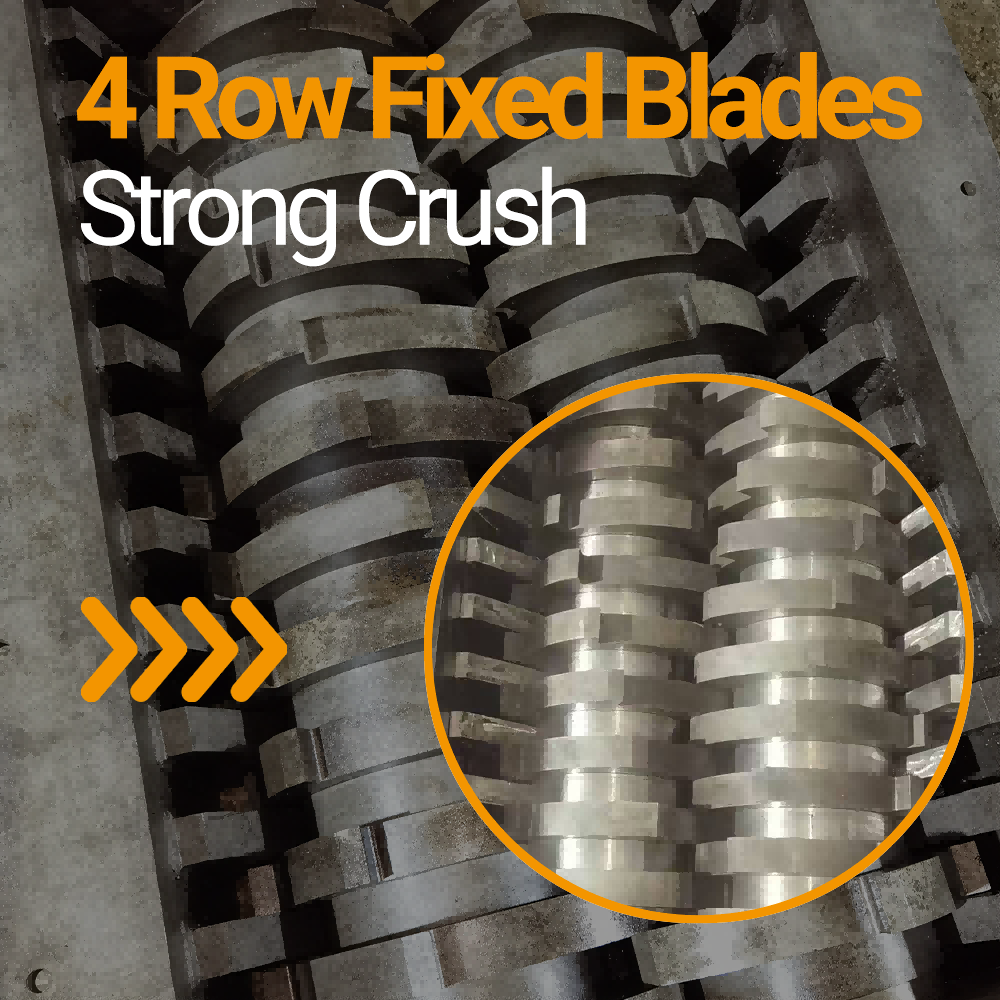

PS Foam Shredding Machine combines stationary and rotary cutters for processing flexible HR foam and quilted waste. Features built-in cooling, adjustable mesh for custom chip sizes, and 900kg/hr capacity with single-operator functionality through advanced foam crusher technology.

Download PDF

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

PU waste, including:Conventional, HR, Viscoelastic, Fabrics and textile scraps

Adjustable shredded foam size thanks to different screens

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Share your contact information – our engineers respond 24/7.

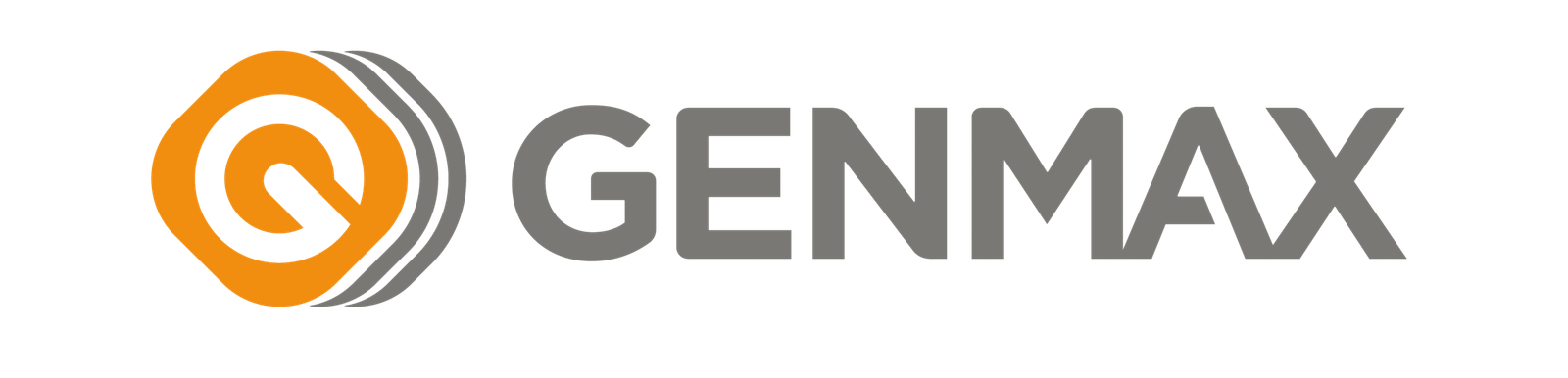

4 rows of fixed knives

3 rows of rotary cutters

Designed with a surrounding circulating water cooling system to prevent overheating and maintain cutting efficiency.

The machine is designed to crush and recycle a wide range of materials including:

High and low-density foam

Foam leather scrap

Cleaning cloth and waste cloth

Bra foam and polyurethane elastomers

Rubber and plastic-rubber elastomers

Hard and soft plastics (from injection molding, blow molding, vacuum forming, etc.)

Packaging, sheets, coils, wood, electronic materials, magnetic materials, and iron-rubber blocks.

It is commonly used in mattress, sofa, shoe pad, vibration/noise insulation, and filling material production industries.

General foam, cloth, and elastomer waste: crushed into 0.5–50mm granules.

High-density foam: can be crushed to below 2mm, suitable for producing hi-poly shoe pads (replacing EVA pads).

Mattress and sofa filling

Cushioning and vibration absorption

Noise insulation materials

Shoe pads with shock absorption, breathability, and moisture absorption properties

Recycled raw material for plastic processing

We provide a standard warranty period of 24 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

Discover how GENMAX can provide the perfect mattress machinery solutions for your business. Click below to send your inquiry and receive a customized proposal from our expert team. Let’s work together to achieve your success!

Share your contact information – our engineers respond 24/7.