Customer Service

Share your contact information – our engineers respond 24/7.

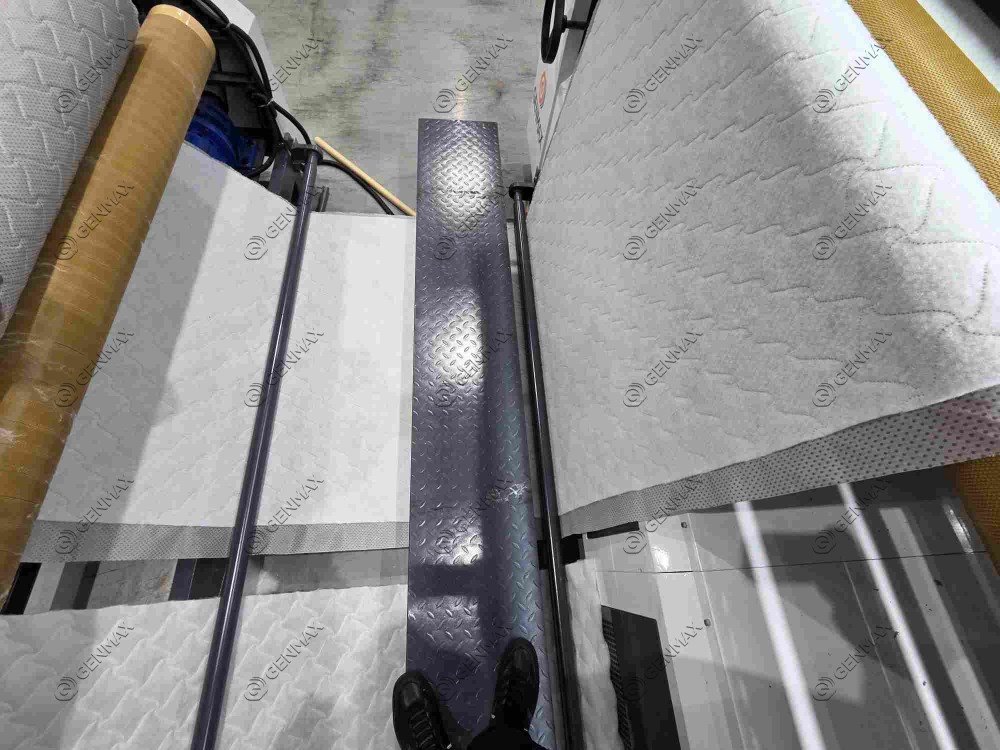

Installation and Commissioning Insights for Ultrasonic Quilting Technology in Specialized Textile Production

Customer feedback often provides valuable insights. A Korean electric blanket manufacturer described their UX4 ultrasonic quilting machine as “very good.”

The installation and commissioning process yielded practical insights. Ultrasonic quilting technology provides alternative methods for electric blanket production. This Korean installation represents one example of the technology’s implementation in textile manufacturing.

Ultrasonic quilting employs high-frequency vibrations for bonding between fabric layers. This process eliminates needle penetration while achieving adhesion strength.

The International Ultrasonics Society reports bond strengths 25-40% higher than traditional stitching in certain applications. The ultrasonic bonding process operates through specific mechanisms.

The UX4 operates at 20m/min production rates. This exceeds conventional quilting methods. Traditional quilting typically averages 4-8m/min according to industry data.

Performance comparison shows operational differences:

This speed difference can increase production capacity during peak demand periods.

Layer management provides operational features:

Technical Setup Requirements

The Korean installation provided implementation data. The customer’s facility required modifications for UX4 operation.

Installation considerations included power supply requirements and cooling system integration. Material feeding system alignment was necessary. Pattern roller customization required setup procedures. Operator training was conducted.

Pattern Roller Configuration

Pattern roller design represented a key installation component. Electric blankets require specific quilting patterns that accommodate heating wire pathways while maintaining product appearance.

Pattern requirements included wire channel integration paths. Heat distribution zones were incorporated. Edge sealing considerations were addressed. Customer-specific design elements required accommodation.

The UX4 accommodates rollers up to 19cm diameter with thickness variations. This provided flexibility for specific applications.

GENMAX UM4 Ultrasonic Quilting Embossing Machine bonds fabrics without needles or thread. It uses ultrasonic technology instead. UM4 features a simple touch screen for easy operation. It handles materials up to 1000 GSM thickness. Production speed is 3 to 5 times faster than traditional quilting methods. The system runs at 300-1200 meters per hour. It works with synthetic fabrics, non-woven materials, polyester, cotton, and spray-bonded textiles. You can create crystal-clear patterns with custom designs.

UM4 Ultrasonic Quilting Machine produces firmly bonded, tear-resistant products. Finished items are ready for immediate use. It’s perfect for home textiles, mattresses, bedding, apparel, electric blankets, and automotive interiors. Each purchase includes complete installation and training. GENMAX experienced engineers provide full support. UM4 operates reliably worldwide.

Production Capabilities

The UX4 processes multiple textile applications. This versatility supports different production requirements.

Applications include bedspreads, comforters, and garment components. The system processes pillowcases, decorative textiles, and bed sheets. Upholstery and outdoor textile applications are possible.

This versatility provides production options during varying demand periods. Manufacturers can utilize equipment for different products as needed.

Material Compatibility

The UX4 processes various material types. This compatibility supports different textile manufacturing applications.

Compatible materials include synthetic fiber fabrics of various weights. Non-woven fabrics and technical textiles process effectively. The system handles bonded cotton and batting materials. Natural fibers including silk and cotton are compatible.

Material types benefit from ultrasonic bonding’s consistent processing characteristics.

Performance specifications include:

Control System Features

The PLC control system provides operational precision for ultrasonic bonding results. This automation supports consistent operation while reducing manual control requirements.

Control capabilities include adjustable bonding pressure settings. Speed coordination operates across system components. Pattern positioning and alignment monitoring support quality. Parameter tracking provides operational data. Diagnostic systems support maintenance scheduling.

Installation Factors

The Korean installation experience identifies implementation considerations. Pre-installation facility assessment supports planning. Operator training programs support effective utilization. Maintenance schedule development supports operational reliability.

Operator Training Requirements

Ultrasonic quilting requires specific operator knowledge compared to traditional methods. Training programs support effective equipment utilization.

Training components include ultrasonic bonding principles and operation procedures. Equipment control procedures are covered. Quality assessment and troubleshooting procedures require attention. Maintenance and cleaning procedures support reliability.

The Korean customer’s operators adapted to the technology effectively. This contributed to their positive assessment of the equipment.