Customer Service

Share your contact information – our engineers respond 24/7.

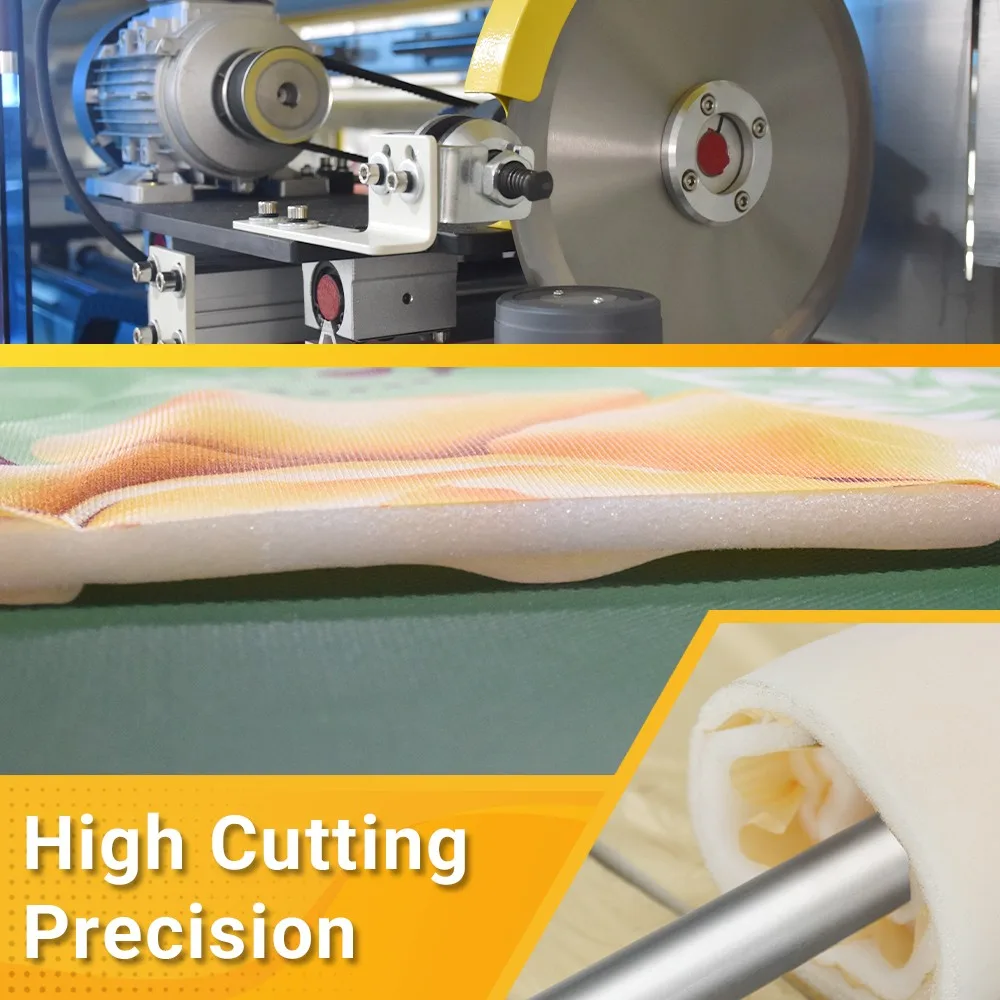

The High Speed Automatic Fabric Cutting Machine is a computerized panel cutter specially designed for mattress panel and border strip production. The machine performs crosscut, slitting, and edge trimming operations on quilted fabric with high precision and efficiency.

Featuring advanced conveyor belt mechanism, the machine integrates seamlessly with quilting machines and rolling devices for continuous production line operations, while maintaining capability for standalone use. The intelligent control system with large touch screen interface and PLC technology provides easy operation and parameter setting.

The machine utilizes encoder data transmission systems supporting any length cutting and multiple cutting specifications, combined with infrared control for safe operation and high cutting precision. Multi-function pneumatic systems handle material pressing, pulling, and blade sharpening automatically, ensuring consistent cutting quality and operational efficiency for mattress fabric processing applications.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

MODEL | CJ4A | CJ5 |

|---|---|---|

Cutting Width | ≤2400mm | ≤2400mm |

Output | 10m/min | 10m/min |

Cutting Thickness | ≤60mm | ≤100mm |

Power | 2KW | 5.5KW |

Voltage | 380/220V,3P,50/60HZ | 380/220V,3P,50/60HZ |

Dimension | 3200*2800*2100mm | 3500*3750*2100mm |

Overall Weight | 1200Kg | 2500Kg |

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Share your contact information – our engineers respond 24/7.

The speed is regulated by a frequency transformer that controls the worm and gear decelerator system.

The machine uses a worm and gear decelerator system for power transmission.

The YHJ features an automatic lubrication system that is computer-controlled, ensuring proper lubrication of the knotting heads.

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

Discover how GENMAX can provide the perfect mattress machinery solutions for your business. Click below to send your inquiry and receive a customized proposal from our expert team. Let’s work together to achieve your success!

Share your contact information – our engineers respond 24/7.