Customer Service

Share your contact information – our engineers respond 24/7.

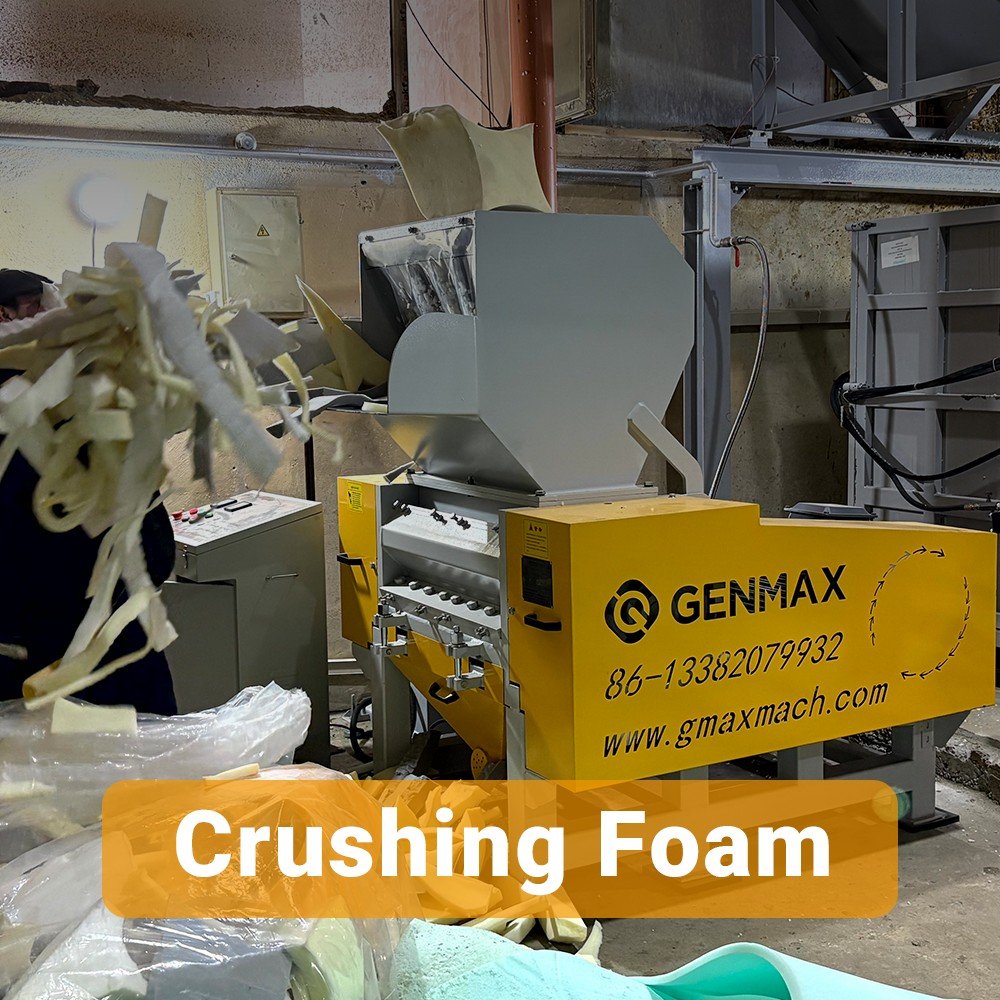

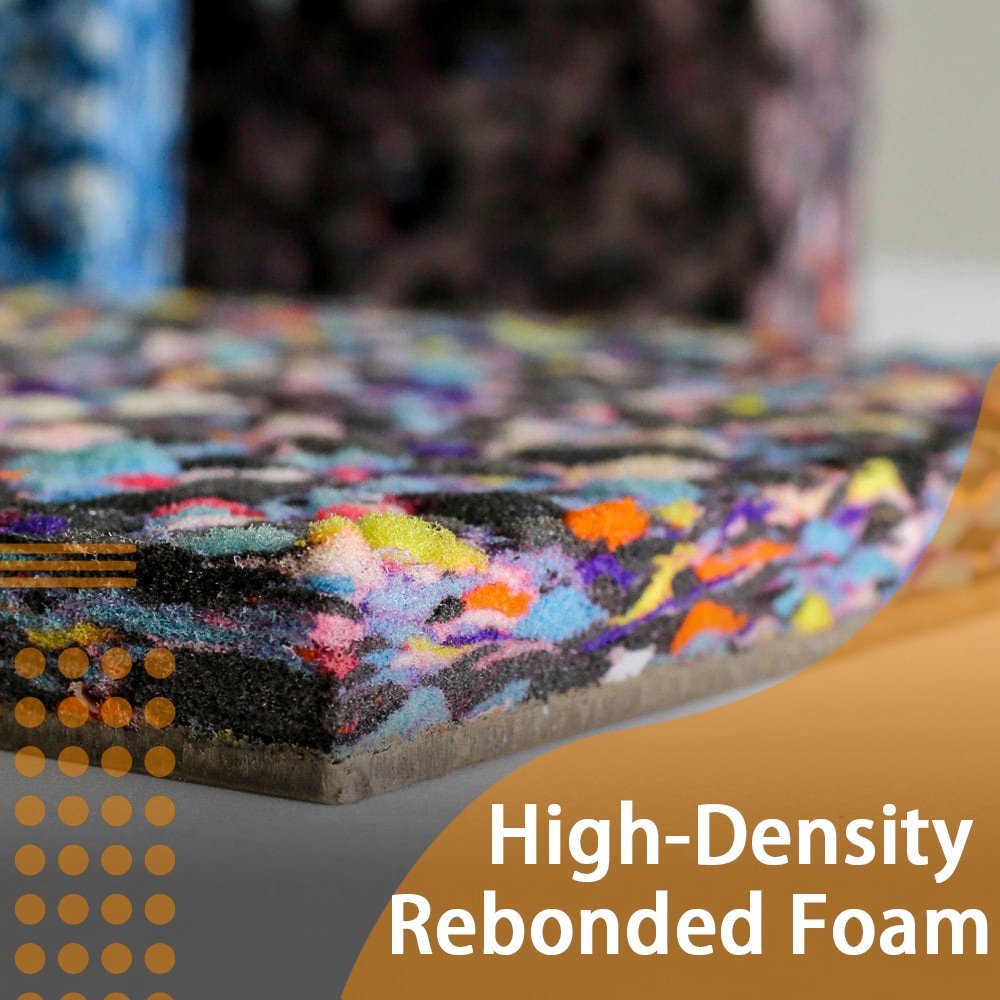

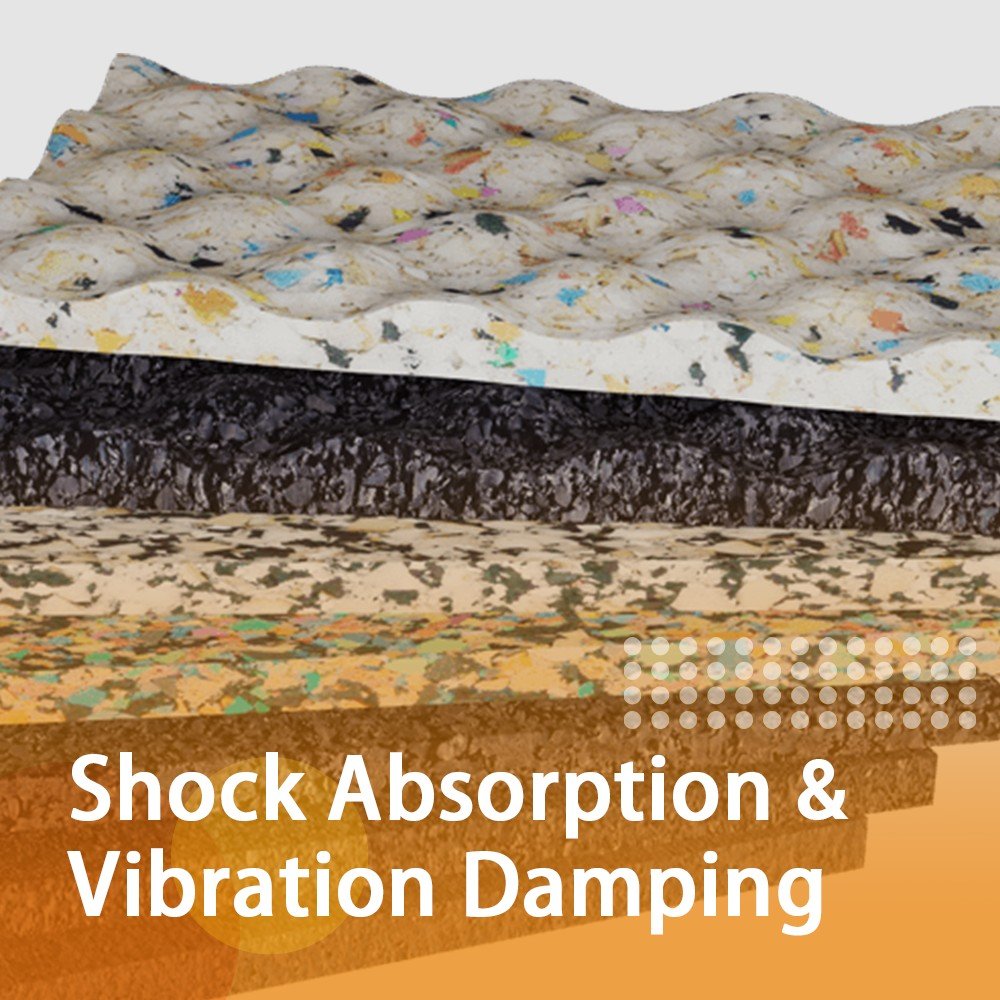

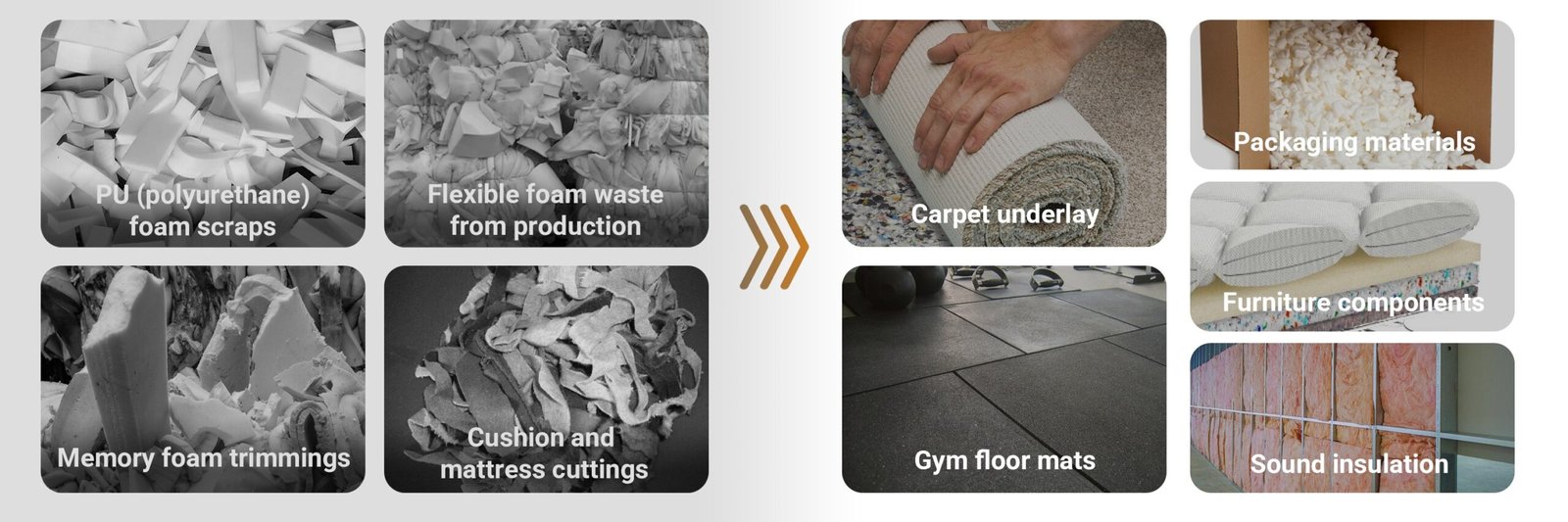

RF Rebonded Foam-Making Machine recycles conversion plant foam waste by rebonding chips into blocks. Features agitator system preventing crystallization, direct discharge into molds, adjustable press unit for density control, optional silo, weight box distribution, and rectangular or cylindrical molds.

Download PDFShare your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Share your contact information – our engineers respond 24/7.

Model | RF02 | RF02-2 | RF02-2 |

|---|---|---|---|

Mixing Tank Capacity | 10m³ | 10m³ | 10m³ |

Mixing Speed | 16RPM | 16RPM | 16RPM |

Output | 10-15PCS/8H | 20-25PCS/8H | 35-45PCS/8H |

Capacity of Boiler | 200L | 200L | 200L |

Top Weighing Stock Bin | No | No | Yes |

Mold Tank Quantity | 1 | 2 | 2 |

Foam Density | 50 to 150 kg/m³ | 50 to 150 kg/m³ | 50 to 150 kg/m³ |

Maximum Oil Jar Pressure | 12T | 12T | 12T |

Number of Oil jar | 1 units | 2 units | 2 units |

Share your contact information – our engineers respond 24/7.

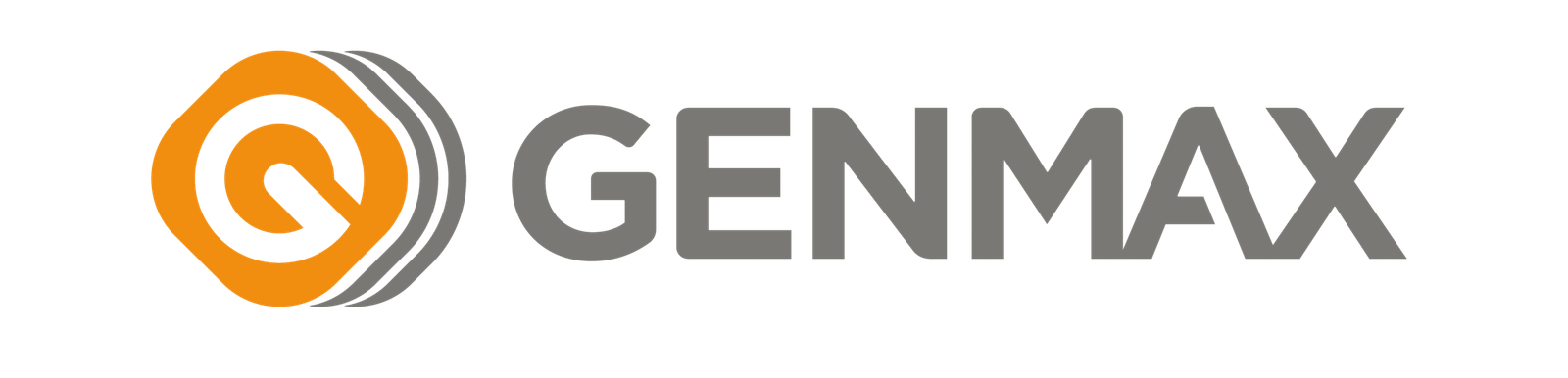

Our machines handle all types of polyurethane foam waste including mattress scraps, furniture foam offcuts, carpet padding waste, and automotive foam components.

All machines come standard with a 200L diesel boiler system. If diesel is not convenient for your facility, we can upgrade to an electric boiler. The electric boiler option is popular for indoor installations or areas with diesel restrictions.

A complete cycle takes 15-25 minutes depending on block size and desired density. With dual mold systems, effective cycle time is reduced to 8-12 minutes per block.

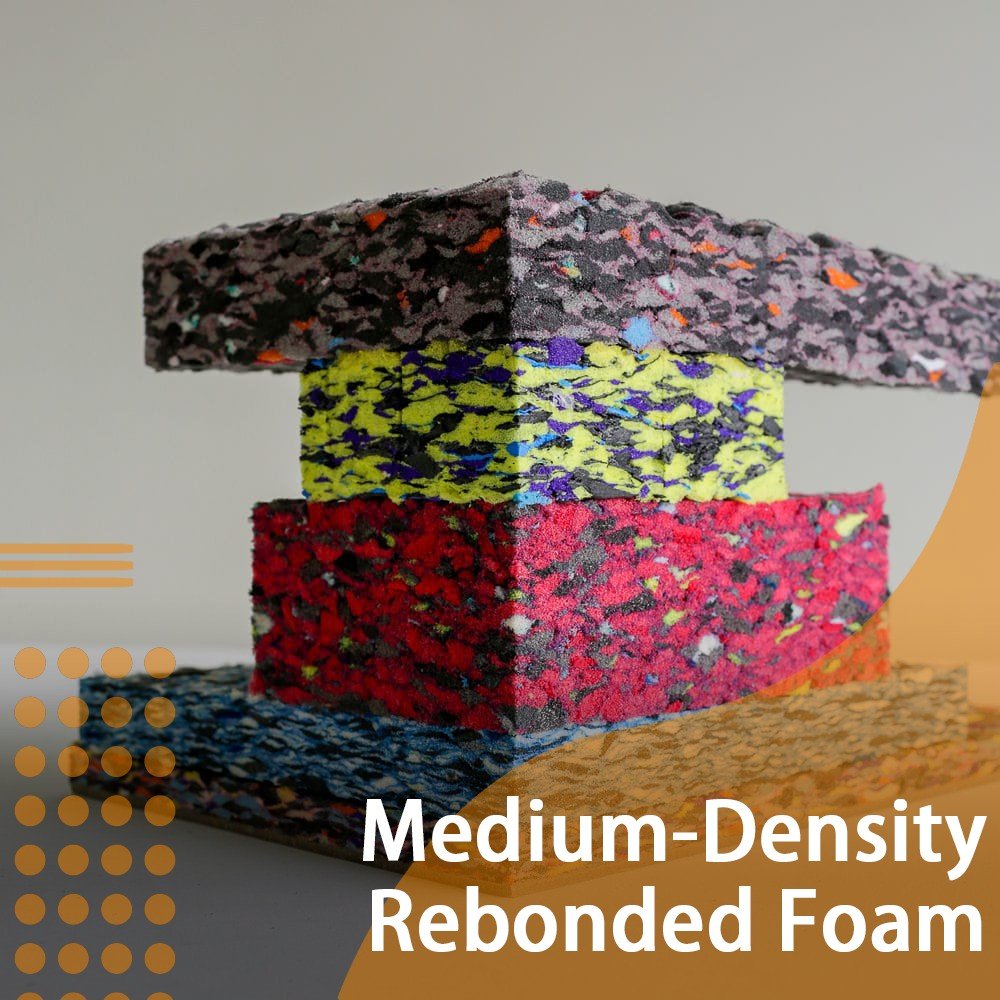

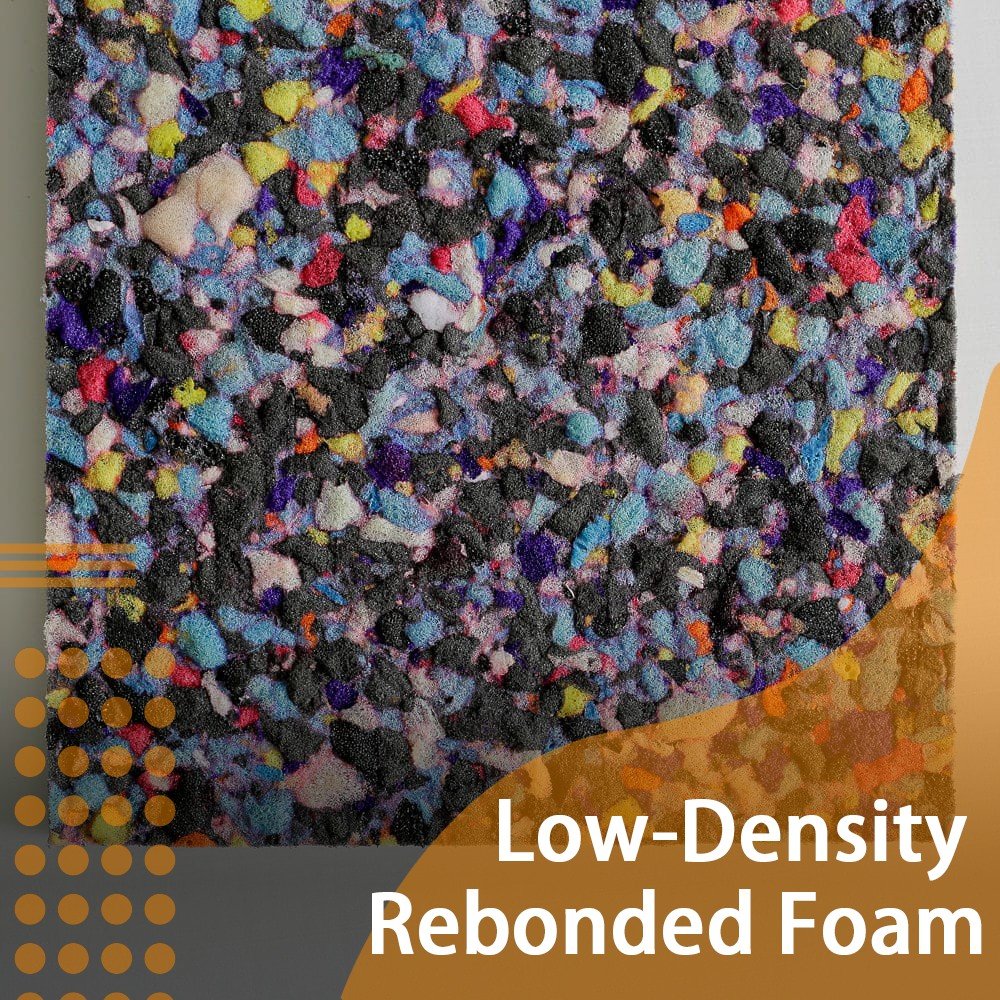

Our machines produce rebonded foam with densities from 50 kg/m³ (lightweight applications) to 150 kg/m³ (heavy-duty industrial use). Density is easily adjustable through pressure and chemical ratio controls.

Standard production uses MDI prepolymer and amine catalyst. We provide supplier recommendations and technical specifications for optimal results.

Yes, we include 40 hours of comprehensive operator training covering machine operation, maintenance procedures, troubleshooting, and safety protocols.

Yes, we specialize in customized solutions. Our engineering team provides customized solutions within 72 hours of receiving detailed requirements.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

Discover how GENMAX can provide the perfect mattress machinery solutions for your business. Click below to send your inquiry and receive a customized proposal from our expert team. Let’s work together to achieve your success!

Share your contact information – our engineers respond 24/7.